Enhancing Product Aesthetic Appeals: The Function of In-Mold Decorations in Production

Enhancing Product Aesthetic Appeals: The Function of In-Mold Decorations in Production

Blog Article

Checking Out the Art of In-Mold Decorations: A Detailed Take A Look At Methods and Technologies

When it comes to in-mold designs, a marriage of imagination and accuracy arises to redefine the possibilities of style. From the advancement of techniques to the advent of advanced materials, the landscape of in-mold decorations is a canvas where advancement thrives.

Development of In-Mold Decor Techniques

The advancement of in-mold decor strategies has dramatically progressed the visual opportunities and effectiveness of item design in producing processes. In the past, standard methods of decorating items commonly involved post-processing actions that were time-consuming and added intricacy to the manufacturing line. With the intro of in-mold design (IMD) techniques, producers can currently flawlessly incorporate decorative components straight into the molding process.

Among the essential improvements in IMD strategies is the ability to accomplish detailed styles with phenomenal information and clearness. By utilizing innovations such as high-resolution printing and advanced mold and mildew surface treatments, suppliers can develop visually magnificent decors on items varying from consumer electronic devices to vehicle parts. Additionally, IMD techniques have enabled the incorporation of textures, coatings, and shades that were formerly hard to attain with typical decor approaches.

Advanced Products and Technologies

Advancing the center of innovation in production, the combination of cutting-edge materials and modern technologies has changed the landscape of in-mold decor techniques. Advanced materials such as unique polymers and nanocomposites supply boosted longevity and aesthetic residential properties, enabling dynamic colors and detailed layouts to be included perfectly right into the end product. These materials additionally provide improved resistance to environmental factors like UV radiation and chemicals, raising the longevity of the decorations.

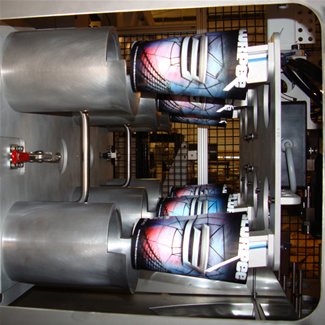

Technical innovations, such as digital printing and 3D surface texturing, have more expanded the opportunities in in-mold designs. Digital printing makes it possible for high-resolution graphics to be straight put on the mold surface, leading to sharp images and precise information. On the other hand, 3D surface area texturing methods create responsive effects that boost both the aesthetic and sensory allure of the decorated items.

The harmony in between sophisticated products and technologies not only elevates the looks of in-mold decors however also boosts efficiency in the production procedure, making it more environmentally pleasant and economical (In-Mold Decorations). This combination paves the method for endless innovative possibilities in the realm of in-mold decoration

Intricate Style Opportunities

Discovering the world of in-mold designs reveals a globe of detailed style possibilities that push the borders of creative thinking and accuracy. Manufacturers are no much longer limited to straightforward patterns or styles; rather, they can currently attain highly detailed and complicated decorations on their products. In-mold decoration strategies allow for the consolidation of great lines, elaborate textures, and vibrant colors that were previously testing to accomplish with other techniques.

Among the vital benefits of in-mold decors is the capability to develop 3D impacts, including deepness and realism to the layout. This strategy opens up a large range of innovative possibilities, enabling manufacturers to reproduce all-natural materials like timber grain or marble with astonishing precision. Additionally, in-mold decorations can be used to create unique coatings such as shiny structures or metallic impacts, improving the overall aesthetic appeal of the product.

Furthermore, in-mold designs offer excellent accuracy, making certain consistency in style across a huge manufacturing run. This level of detail and accuracy is essential for sectors where branding and layout stability are extremely important, such as in the automotive or customer electronics sectors. On the whole, the intricate layout possibilities paid for by in-mold decorations remain to revolutionize the method items are enhanced and made in numerous sectors.

Sector Applications and Innovations

Building upon the intricate style opportunities promoted by in-mold designs, various markets are using innovative applications to raise product visual appeals and performance. In the auto market, in-mold decorations are being used to create aesthetically enticing interior and exterior parts with complex textures and patterns. This not only boosts the general look of cars but likewise adds to an extravagant feeling. Additionally, the customer electronic devices sector is leveraging in-mold decorations to create streamlined and modern-day tools with seamless designs that integrate switches and displays into the product surface. This causes a much more easy to use and aesthetically pleasing end product. Additionally, the household home appliance industry is incorporating in-mold decorations to enhance the look of appliances such as refrigerators, ovens, and washing makers, making them a lot more aesthetically appealing in click resources modern home settings. By welcoming in-mold decorations, these sectors are setting brand-new standards for item style and aesthetic appeals, giving customers with visually striking and ingenious products.

Future Patterns in In-Mold Decorations

Welcoming progressing technologies and layout techniques, the realm of in-mold designs is poised to witness considerable shifts and developments in the close to future (In-Mold Decorations). Such innovations not just improve the aesthetic allure of the items but also add practical value, making in-mold designs more than just a design element.

Moreover, sustainability is coming to be a vital emphasis in the area of in-mold decors. Producers are exploring environmentally friendly materials and procedures to lower ecological effect while keeping top quality criteria. This fad aligns with the growing consumer need for lasting items, pushing the sector in the direction of more ecologically aware techniques.

Additionally, personalization and customization are anticipated to play a substantial role in the future of in-mold decorations. With developments in digital printing technologies and software program capabilities, manufacturers will certainly have the ability to use even more tailored solutions to satisfy individual consumer choices. This pattern is most likely to drive development and creative thinking in the design and production procedures, giving tailored and distinct products to customers.

Final Thought

In-mold decor techniques have actually progressed dramatically, supplying innovative materials and innovations that enable detailed style possibilities. These advancements have located applications throughout different industries, leading to constant improvements and future fads in in-mold designs. The art of in-mold decors continues to press anonymous borders and create new possibilities for enhancing product looks and functionality.

Building upon the intricate layout opportunities helped with by in-mold decors, various sectors are taking advantage of ingenious applications to raise product aesthetics and functionality. Furthermore, the consumer electronics industry is leveraging in-mold designs to create modern-day and smooth gadgets with smooth layouts that integrate switches and displays right into the product surface area. By accepting in-mold decors, these industries are setting new requirements for item style and looks, giving customers with innovative and visually striking items.

Report this page